Reliable

Machines fail when foreseeable project-specific conditions aren’t carefully considered when their hydraulics are designed. We understand this reality and pay close attention to all project details - obvious and obscure.

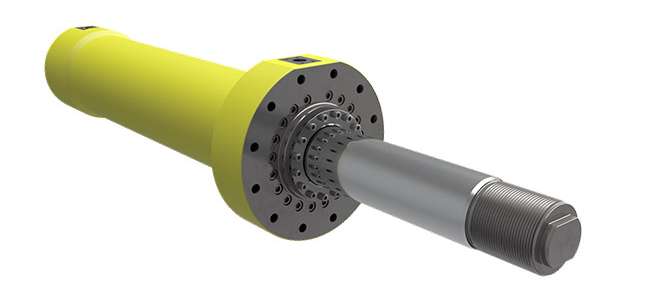

Passion invests the time and resources to investigate the “what ifs” and to appropriately size components, select materials, and include features that prevent failures. We don’t leave anything to chance; we examine rod buckling, bearing wear, transient overloads, contamination, temperature extremes, corrosion, and hundreds of other concerns that impact reliability.

Superior Value

Passion’s value promise is not encapsulated by hollow expressions or tired clichés. Our commitment is witnessed by the investments we make in the processes and materials that go into our products.

Superior value is our standard. All Passion products include upgraded materials, painstaking attention to detail, repeated design iterations, significant quality assurance processes, and more.

We take our commitment to superior value as an obligation to consider your short, intermediate, and long-term needs.

Safe

Every component and system Passion Engineering ships is designed, built, and tested with safety in mind. Holding a conservative engineering approach, we strive to consider and address every possible failure mode and hazard.

Customer requirements and specified codes, rules, and standards are respected. Complete design documentation is provided, as required, to verify compliance.

Passion Engineer’s embrace of safety doesn’t wrap up with the design stage; equal care and diligence are devoted to our manufacturing, quality assurance, NDE, testing, and manual development efforts.