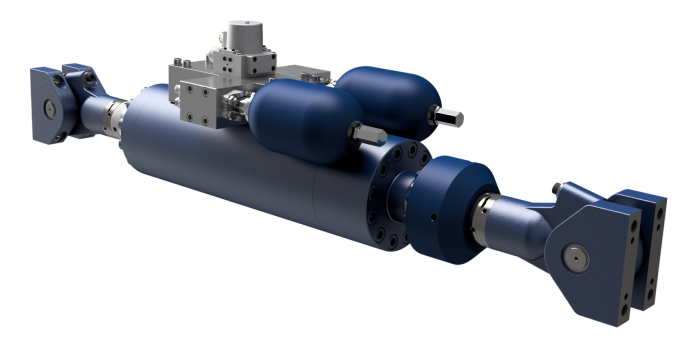

Our custom large bore cylinders, hydraulic actuators, and hydraulic systems for test machines are designed to accommodate the unique needs of their parent systems. We engineer hydraulic test system solutions for precise, stable, and responsive control of position, speed, acceleration, and force:

- Low-friction seals, specially prepared sealing surfaces, and other provisions for high cycle longevity

- Carefully considered weld geometries, metallurgy, structural element details, and pre-loaded joints for high-cycle fatigue resistance

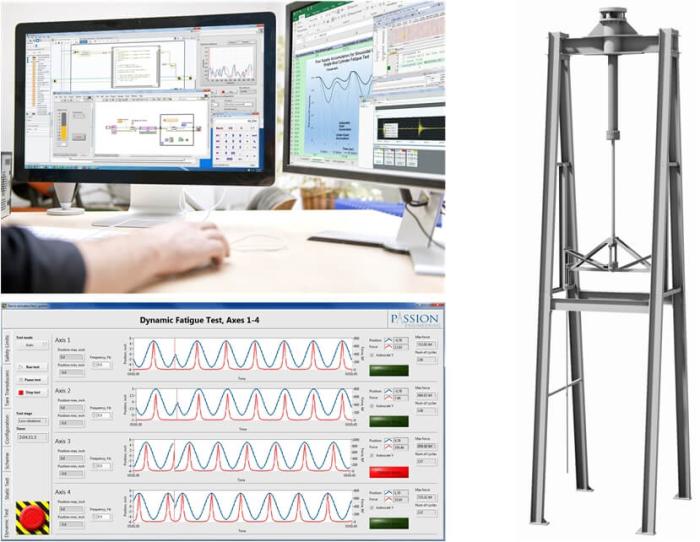

- Systems designed for operational flexibility to accommodate future tests, modes, and sequences

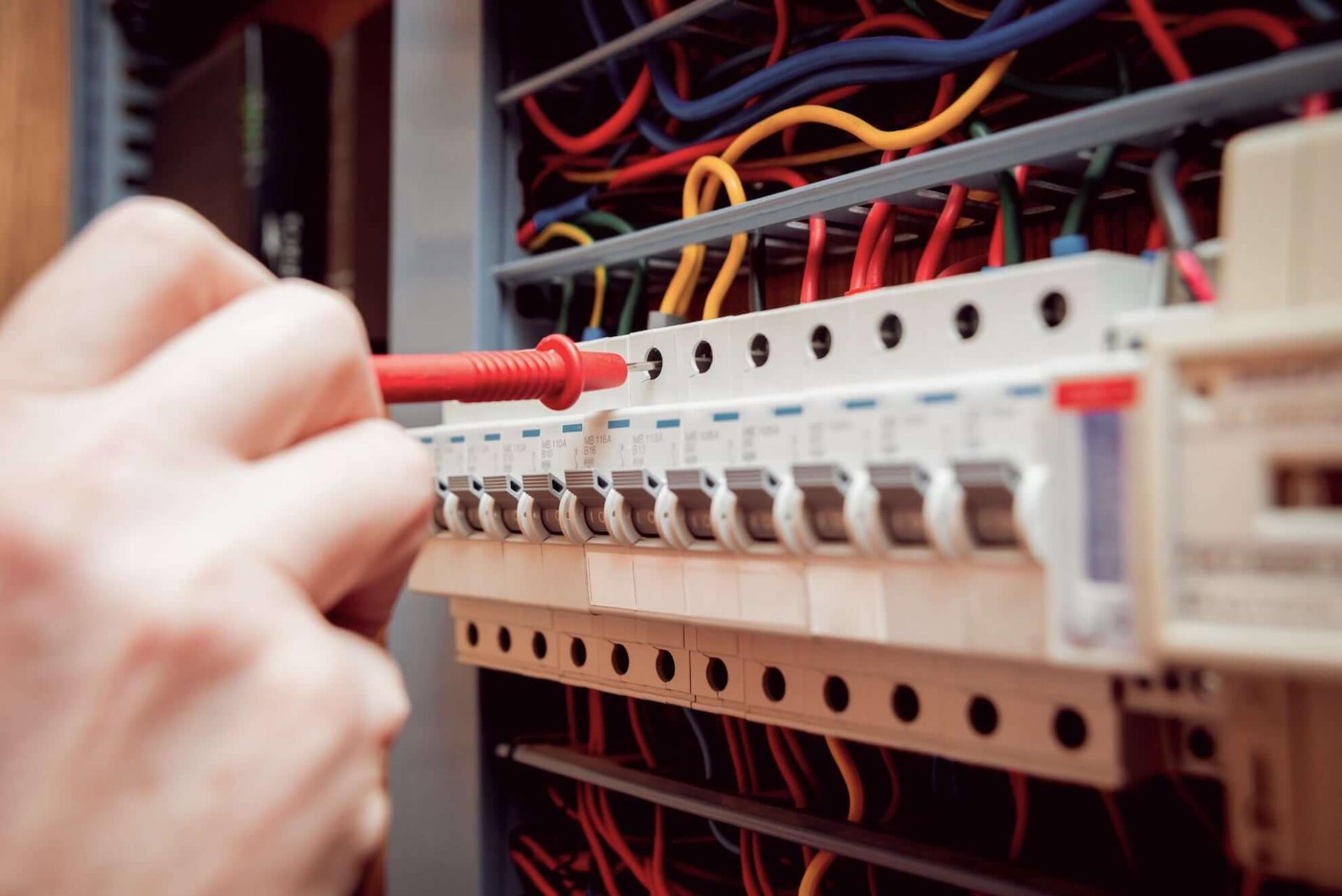

- Control systems with easy to use and intuitive graphical interfaces

- Telemetry systems with data acquisition and logging

- Special accommodations for specific test environment requirements; special fluids, extreme temperatures, extreme pressures, shock and vibration, and others

- Specialty hydraulic systems, mechanisms, and structures, engineered for the high loads and stored energies of large bore cylinder systems

- Thoughtful attention to safety and inclusion of appropriate protections against unintended motions, excessive pressures and forces, hydraulic line breaks, and other hazards