Hydraulic Cylinder Mounts

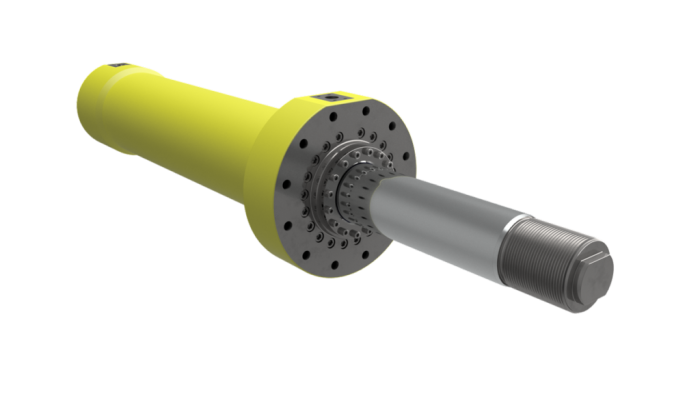

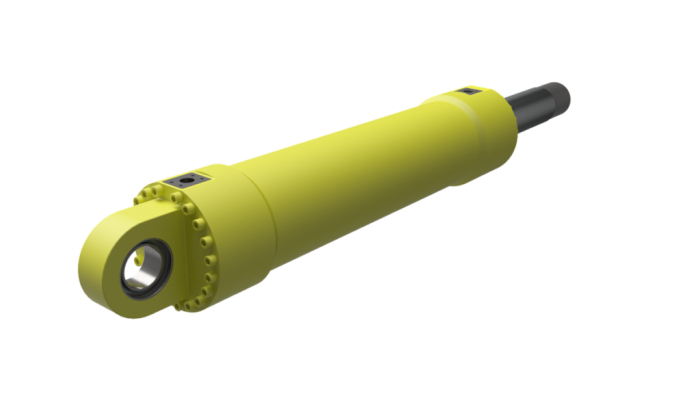

Head Flange

Head flange mounts are available in round, square, and rectangular configurations and provide straight-line force transfer on cylinder centerlines. On standard/cataloged cylinders, these mounts are sometimes limited to applications with primary tensile (pulling) loads and low thrust loads to limit flange bending and fastener stresses. Custom cylinder designs can eliminate this limitation when this mount is preferred for high thrust applications.

Cylinder head flanges mount to rigid machine members with machined locating pilots and mating surfaces that are perpendicular to the line of force. These mounts can be exceptionally strong and rigid but are also less accommodating of machine misalignments.

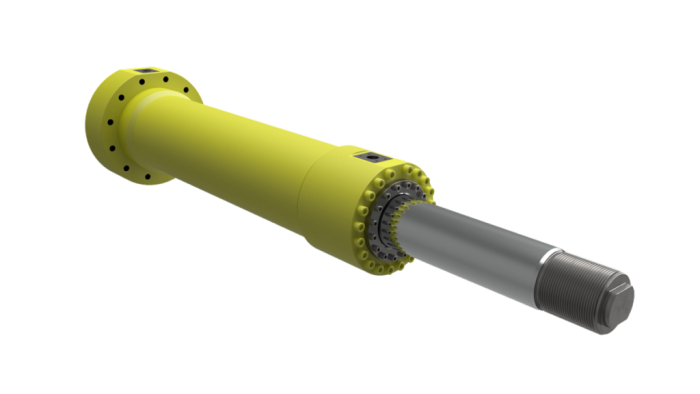

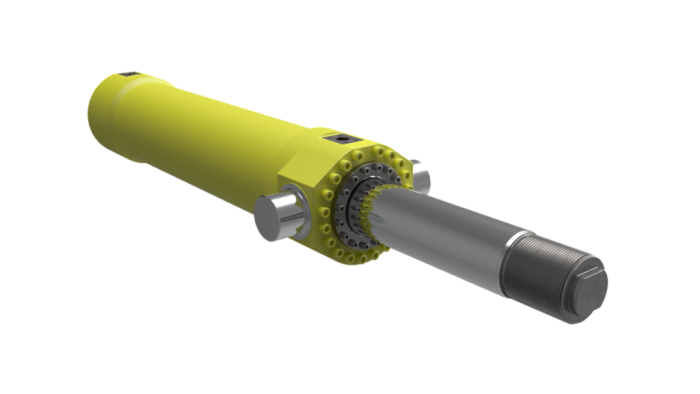

Cap Flange

Head flange mounts are available in round, square, and rectangular configurations and provide straight-line force transfer on cylinder centerlines. On standard/cataloged cylinders, these mounts are sometimes limited to applications with primary tensile (pulling) loads and low thrust loads to limit flange bending and fastener stresses. Custom cylinder designs can eliminate this limitation when this mount is preferred for high thrust applications.

Cylinder head flanges mount to rigid machine members with machined locating pilots and mating surfaces that are perpendicular to the line of force. These mounts can be exceptionally strong and rigid but are also less accommodating of machine misalignments.

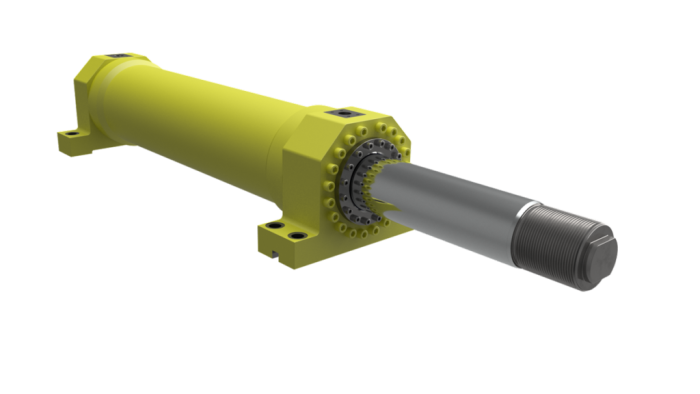

Side Lug

Side lug mounts and their variants are designed to transfer forces in a straight line to linearly guided loads. They provide a convenient means to connect small or light-duty hydraulic cylinders to their machines.

Side lug mount cylinder mounting surfaces should be flat and parallel to the cylinders’ planes of motion. Since their mounting surface planes and centerlines are offset, side lug mount cylinders experience turning moments that require consideration. Machine frames should be stiff enough to withstand these turning moments without significant deflections.

Side lug mount cylinders are often installed with thrust keys or dowels for positioning purposes and to simplify their bolted machine joints.

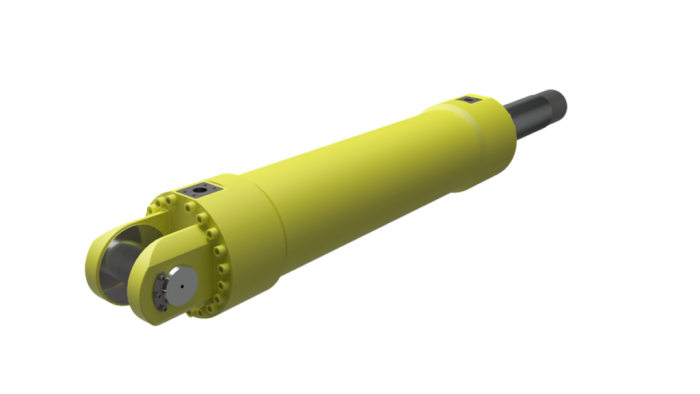

Cap Clevis

Cap clevis mounts are popular mounts intended for non-linear, single-plane machine motions. They self-align (single plane) and protect against undesirable side loads that can accelerate wear or cause harm. Cap clevis mount cylinders are usually easy to install and provide flexibility to machine designers.

These cylinders require rod-end attachments that pivot. Cap clevis mount cylinders are less resistant to buckling than rigidly mounted cylinders and may require large rods and stop tubes in high-thrust, long-stroke applications.

Cap Spherical Eye

Cap spherical bearing attachments are intended for non-linear, single-plane machine motions where minor out-of-plane motions or misalignments are unavoidable. They self-align and protect against undesirable side loads that can accelerate wear or cause harm. Spherical bearing attachment cylinders are usually easy to install and provide flexibility to machine designers.

These cylinders require spherical bearing rod-end attachments. Spherical bearing cylinders are less resistant to buckling than rigidly mounted cylinders and may require large rods and stop tubes in high-thrust, long-stroke applications.

Head Trunnion

Head trunnion mounts serve applications involving non-linear, single-plane machine motions. They self-align (single plane) and protect against undesirable side loads that can accelerate wear or cause harm. Carefully designed, head trunnion mount cylinders can be easy to install.

Head trunnion mount cylinders enjoy improved column stability over other pivoting cylinder attachment types and can provide longer maximum strokes in high-thrust applications, especially when oriented vertically, compared to similarly dimensioned cap pivot mount cylinders.

Trunnion mount cylinders require rod-end attachments that pivot.

Since head trunnion mount cylinders with long strokes and horizontal orientations can experience moments that increase their bearings’ loads, such cylinders should be carefully engineered to prevent premature wear.

Where out-of-plane motions and misalignments cannot be avoided, trunnion mount cylinders can be mounted with two-axis gimbal assemblies to provide excellent self-aligning capabilities. In these cases, cylinder rod-end attachments should be similarly gimbaled or employ spherical bearings.

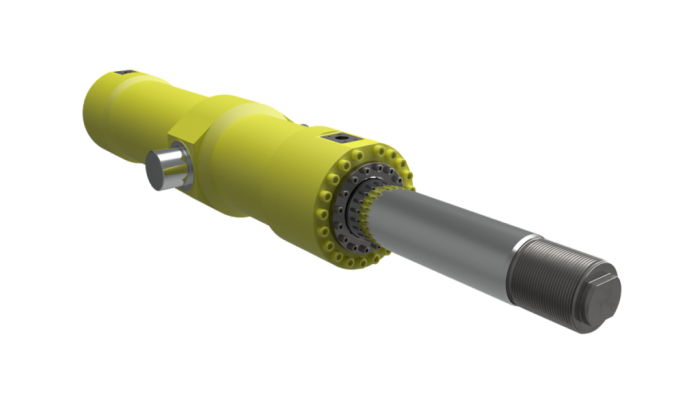

Intermediate Trunnion

Intermediate trunnion mounts serve applications involving non-linear, single-plane machine motions. They self-align (single plane) and protect against undesirable side loads that can accelerate wear or cause harm. Carefully designed, intermediate trunnion mount cylinders can be easy to install.

Trunnion mount cylinders require rod-end attachments that pivot.

Intermediate trunnion mount cylinders with long strokes and horizontal orientations can be balanced to significantly reduce moments that would otherwise increase the loads on their bearings.

Where out-of-plane motions and misalignments cannot be avoided, trunnion mount cylinders can be mounted with two-axis gimbal assemblies to provide excellent self-aligning capabilities. In these cases, cylinder rod-end attachments should be similarly gimbaled or employ spherical bearings.

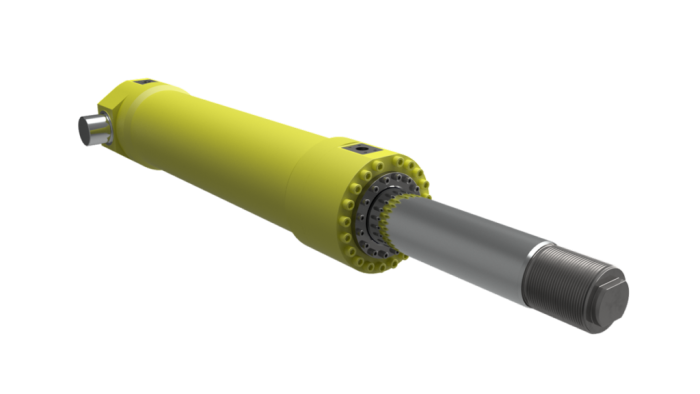

Cap Trunnion

Cap trunnion mounts serve applications involving non-linear, single-plane machine motions. They self-align (single plane) and protect against undesirable side loads that can accelerate wear or otherwise cause harm. Carefully designed, cap trunnion mount cylinders can be easy to install.

Trunnion mount cylinders require rod-end attachments that pivot.

Where out-of-plane motions and misalignments cannot be avoided, trunnion mount cylinders can be mounted with two-axis gimbal assemblies to provide excellent self-aligning capabilities. In these cases, cylinder rod-end attachments should be similarly gimbaled or employ spherical bearings.

Get In Touch

Perfect Your Hydraulic Machines

Elevate machine performance and simplify projects with hydraulics engineered for your application.